I have been working with Schneider Electric in Plymouth of behalf of ConsultQA since August 2017 to integrate and transition the existing separate quality, environmental and health and safety management systems.

Schneider Electric manufacture a range of products under the Drayton and Eberle brands, the Drayton product portfolio is split into 3 areas:

- Heating (thermostats, programmers, controllers, Internet-connected products including the new connected Wiser product range)

- TRV (Thermostatic Radiator Valves)

- Traditional (automotive, pressure switches) including L Controls (safety devices for boilers)

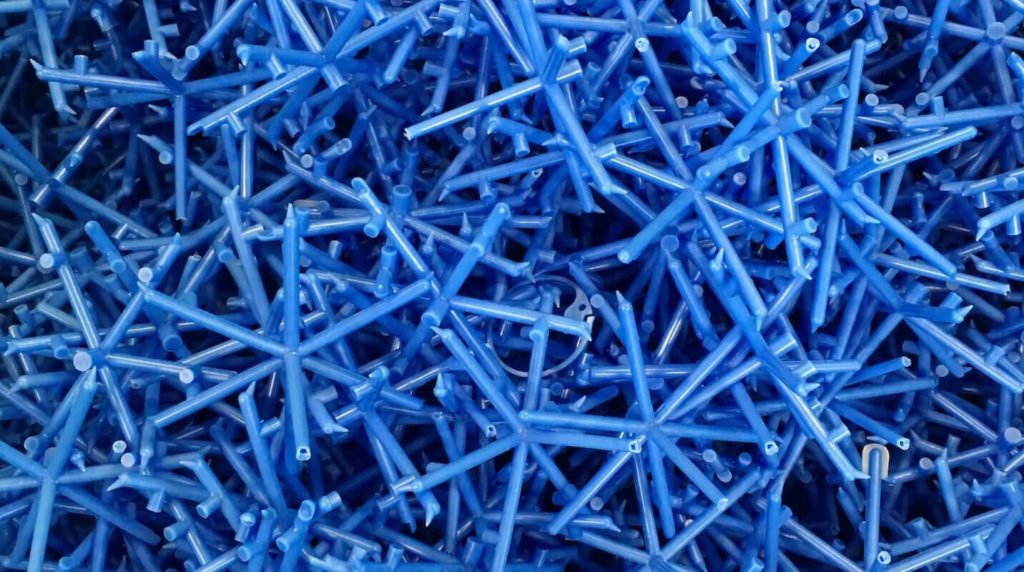

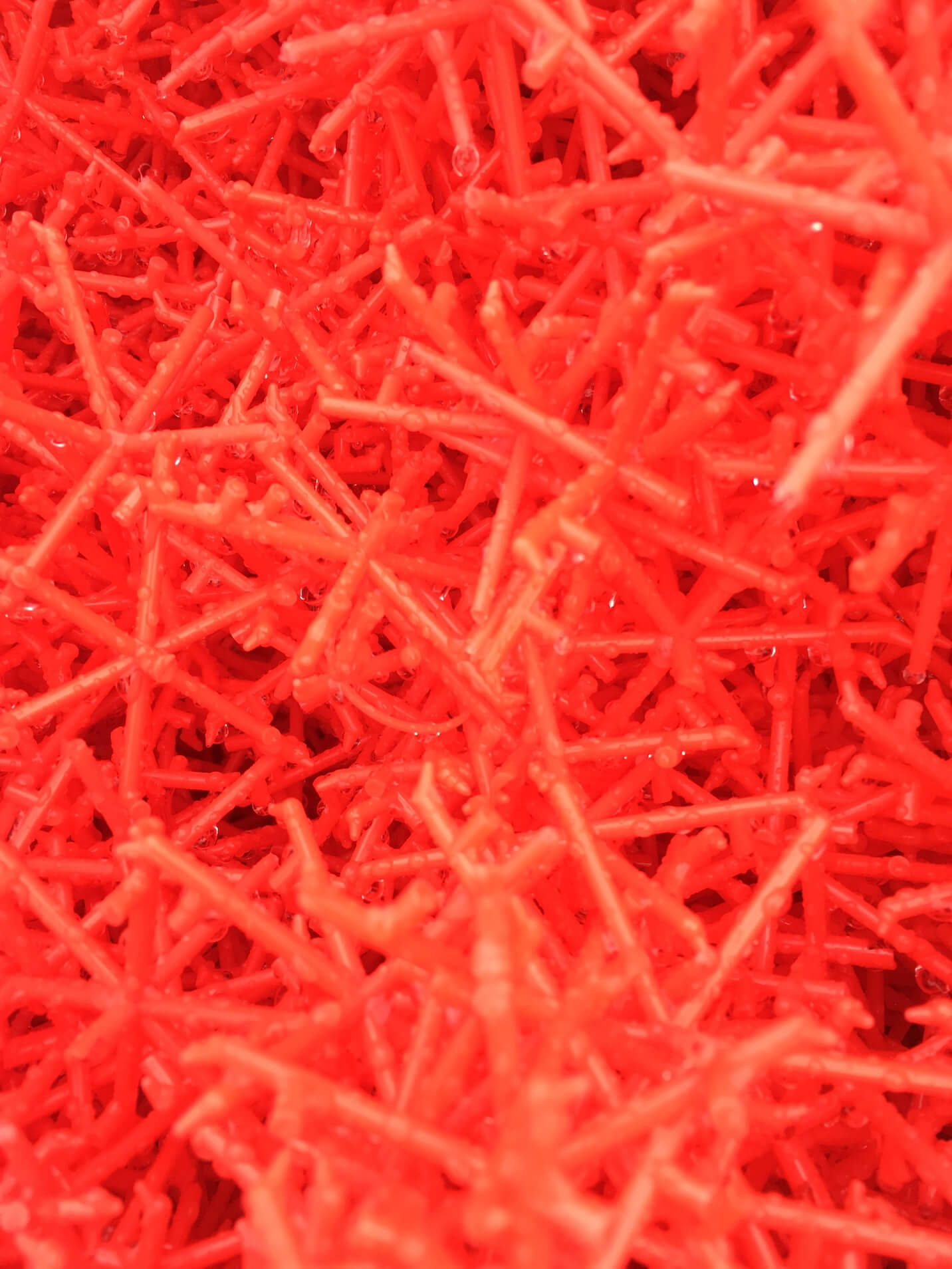

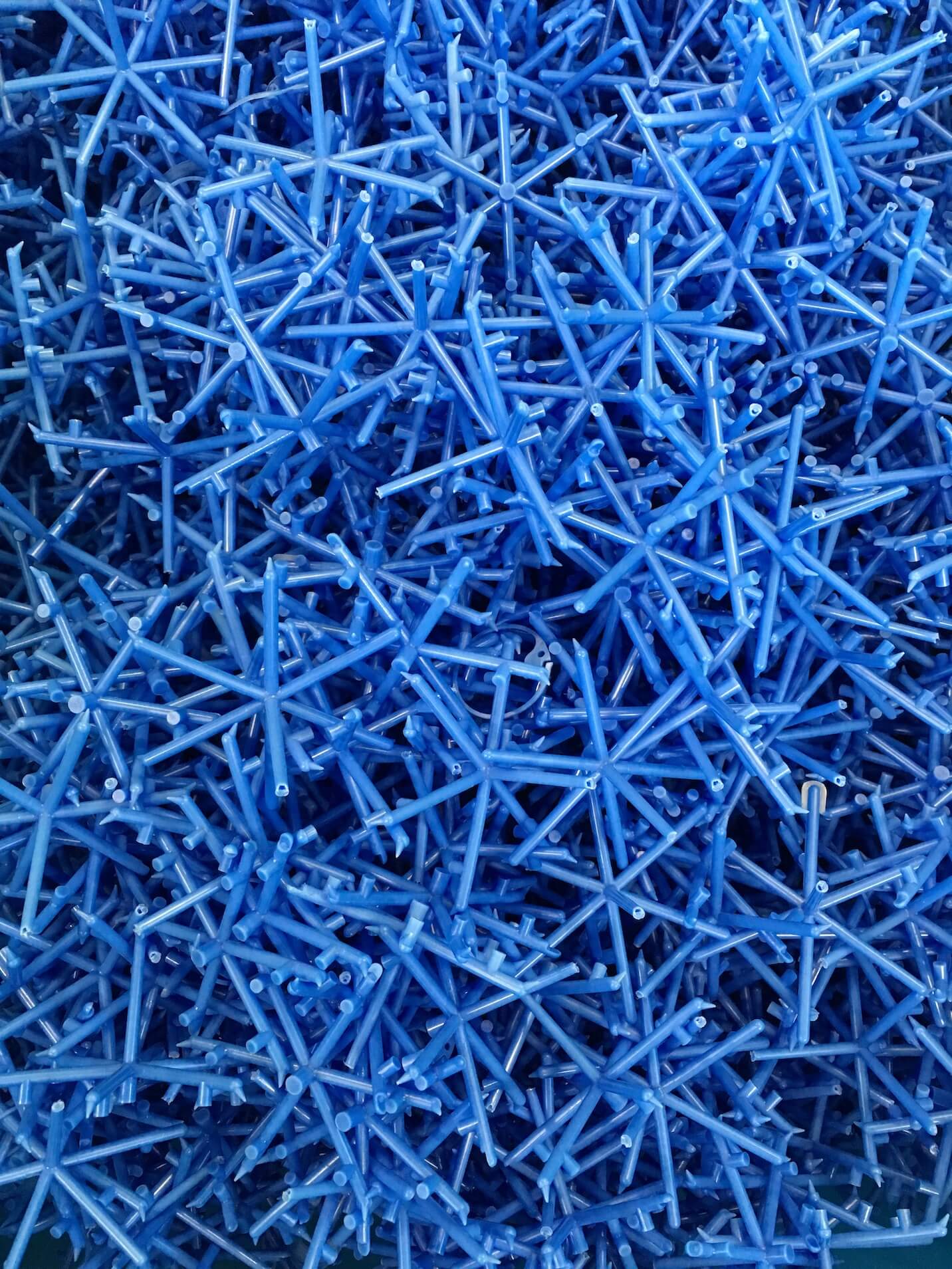

My favourite area of Production is ‘Traditional’ as this is the oldest area of the company and relies on an extremely skilled and long serving team who manufacture the components and final products more or less from scratch. The other area I find fascinating is the Injection Moulding area where 1000s of components are manufactured every day to supply all the production lines.

I find this area absolutely fascinating as the design of the mould and tools is critical in reducing the amount of sprue and waste – in fact some of the new tools produce no sprue at all.

Culturally, the quality management system had previously been managed by the Quality Department and the combined Health, Safety and Environmental management system was managed by the HSE Coordinator. There were two (and sometimes three!) separate sets of documentation, two separate certification bodies (BSI and Independent European Certification Ltd) and two separate audit schedules.

Our first task was to carry out a Gap Analysis against the new requirements of ISO 9001:2015 and ISO 14001:2015 and to identify what documents we actually had. We then started to work out where the duplication was and what we could get rid of (always my favourite bit of a project!). One of the key things we wanted to achieve with this project was the simplification of the management system as well the integration into normal business processes as there was a perception that the ‘quality’ aspects of the business belonged to the Quality Department.

A large part of the project was the creation of a new integrated manual which covered the requirements of the quality, environmental, health and safety management systems. Although there is now no requirement for a manual in the ISO standards, all my direct and associate clients have decided to keep one to act as a useful summary / signposting document as well as a training tool for new employees or sub-contractors.

Having been working with and mentoring the internal team during the project, I have stepped back from leading the audits as the internal team have now completed their Lead Auditor training and taken on this task internally – I am really proud of how the team has developed over the last two years.

Our next step is migrating the existing integrated system to the meet the new ISO 45001:2018 requirements which is planned for Autumn 2019.